DB20 Portioning System in Video

The DSI Dual Blade 20 Portioning System is the latest addition to JBT’S of portioning equipment.

This already includes the industry-leading DSI800 series waterjet portioning system.and the DSI Adaptive 3D portioning system, which uses servo-positioned horizontal slicer to produce high yields of template and thickness-controlled portions.

This already includes the industry-leading DSI800 series waterjet portioning system.and the DSI Adaptive 3D portioning system, which uses servo-positioned horizontal slicer to produce high yields of template and thickness-controlled portions.

The DSI Dual Blade 20 Portioning System is the latest addition to JBT’S of portioning equipment.

This already includes the industry-leading DSI800 series waterjet portioning system.and the DSI Adaptive 3D portioning system, which uses servo-positioned horizontal slicer to produce high yields of template and thickness-controlled portions.

This already includes the industry-leading DSI800 series waterjet portioning system.and the DSI Adaptive 3D portioning system, which uses servo-positioned horizontal slicer to produce high yields of template and thickness-controlled portions.

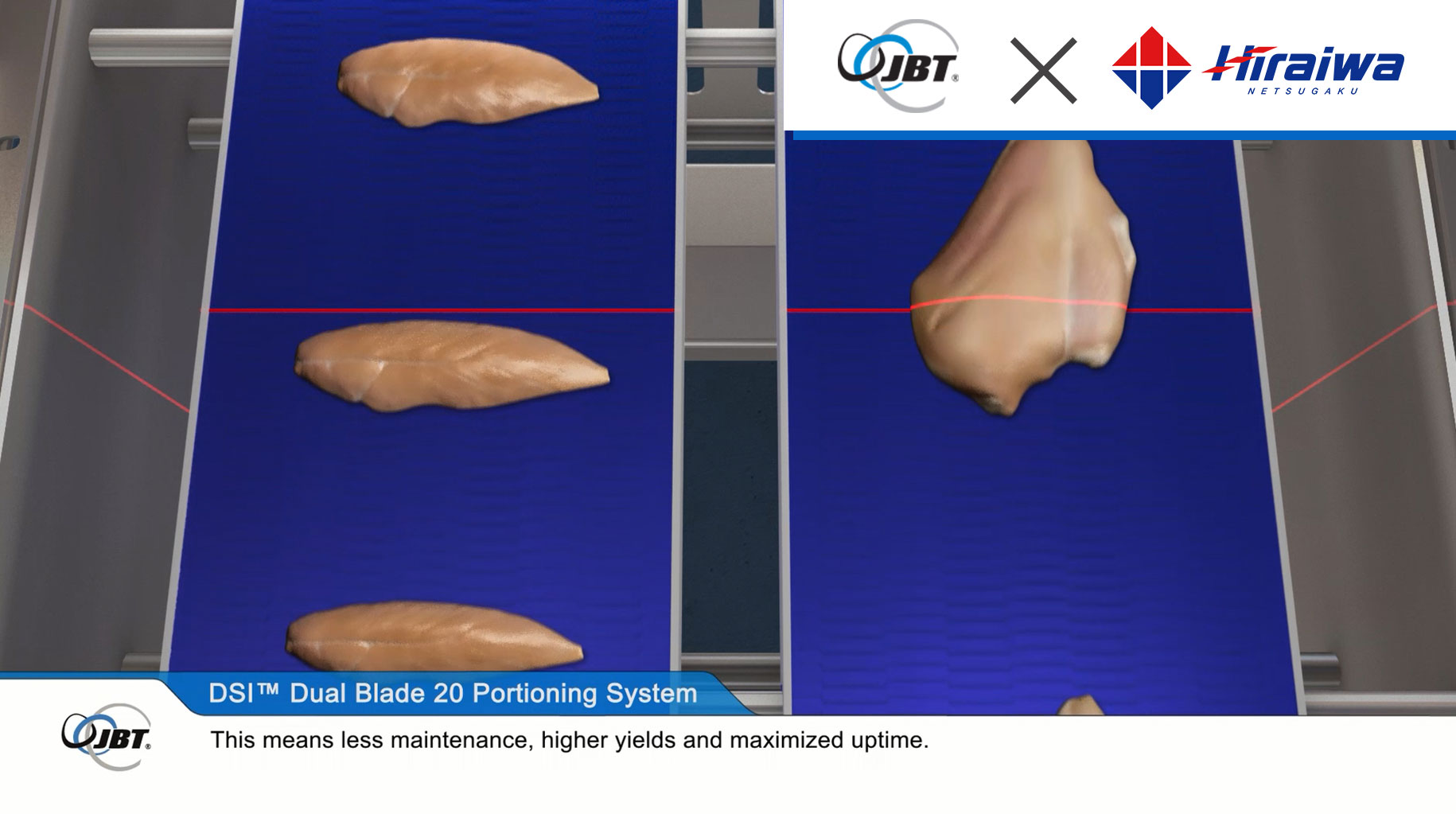

The new DSI DB20 system uses a unique blade to cut portions.

This new blade portioner is consistently accurate, hygienic, easy-to-operate and in spite of its compact design. It can easily manage high throughput linear portioning of a wide range of applications.

These includes chicken nuggets, stakes, the regular cuts of chicken used to make various type.

This new blade portioner is consistently accurate, hygienic, easy-to-operate and in spite of its compact design. It can easily manage high throughput linear portioning of a wide range of applications.

These includes chicken nuggets, stakes, the regular cuts of chicken used to make various type.

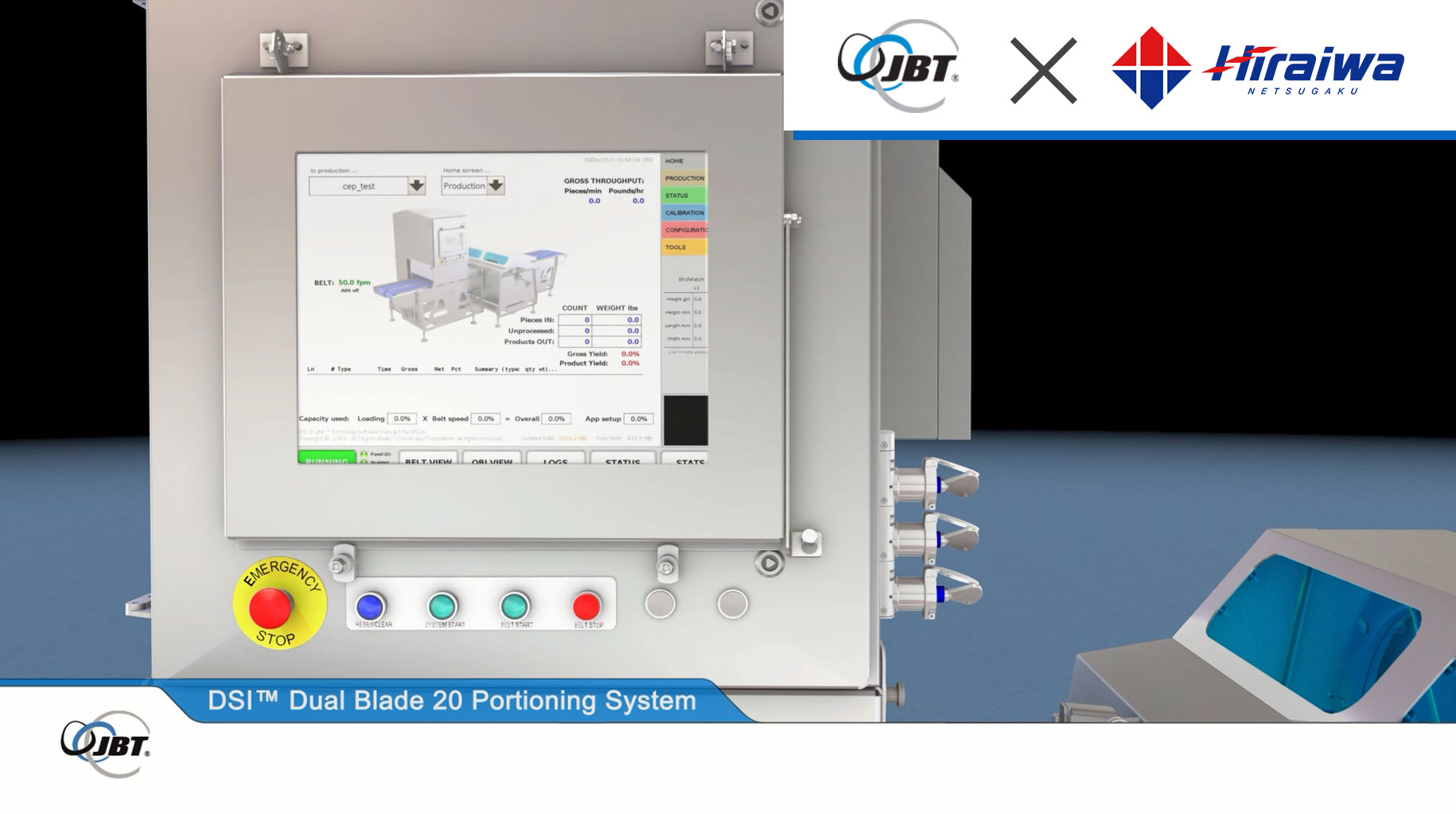

The newly developed “DSI Q-LINK” potion software achieves high yields by simply entering a simple program on the large touch screen.

This software is compatible with all DSI potion systems and is easy to operate. In addition, remote support is perfect.

This software is compatible with all DSI potion systems and is easy to operate. In addition, remote support is perfect.

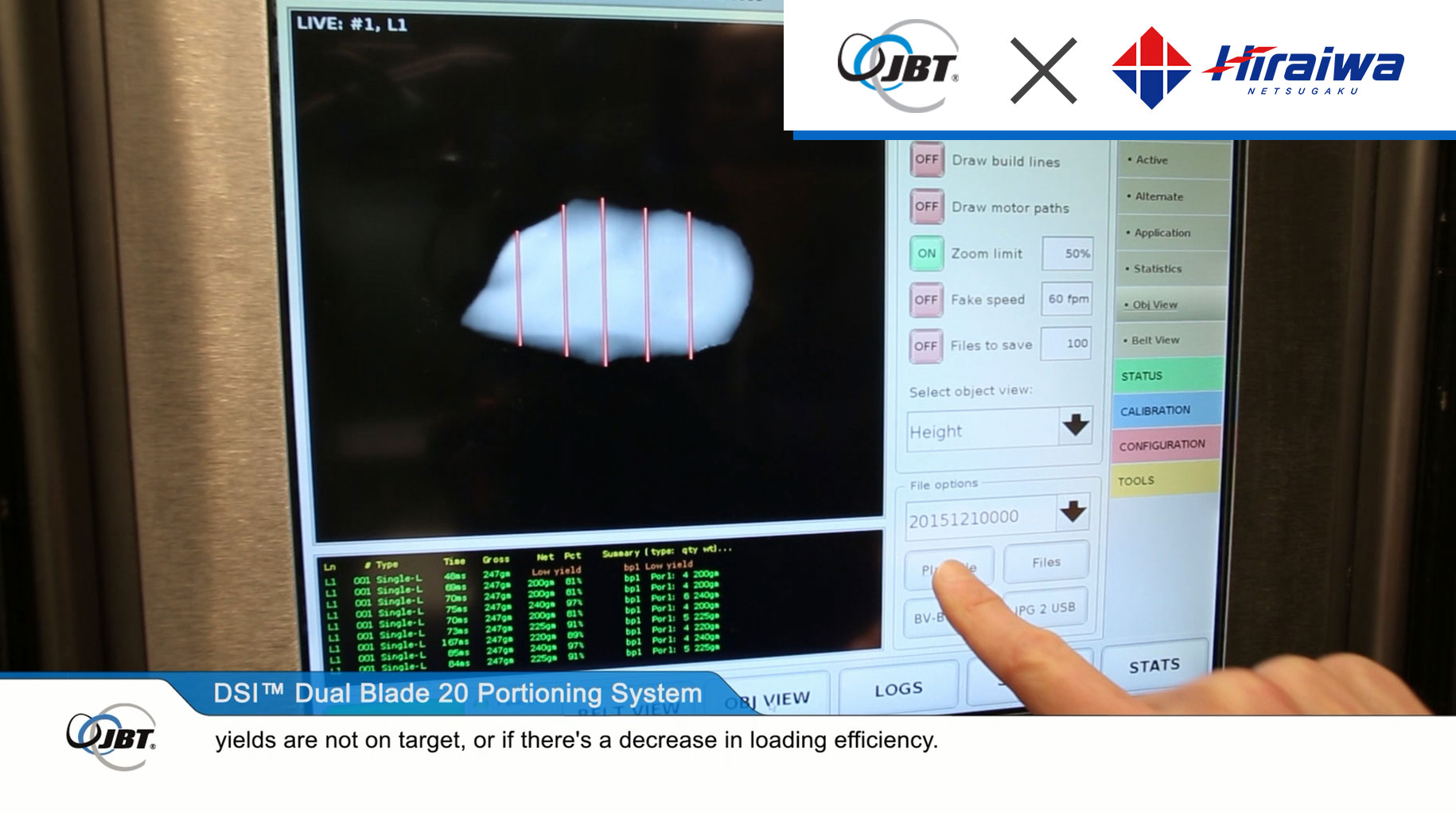

Applications can be changed at the touch of a button or configured to notify you when, for example, a blade becomes dull. Yields are not on target or if there is a decrease in loading efficiency.

A good scanning and vision system detects the shape of the product and the difference between fat and lean meat and makes automatic adjustments. This reduces maintenance time, improves yield, and

maximizes operating time.

The dual lane system allows you to run different applications simultaneously in each lane while optimizing yield, as well as combining potions, strips, and nuggets with programmed weight or dimensional controls with angle cuts.

maximizes operating time.

The dual lane system allows you to run different applications simultaneously in each lane while optimizing yield, as well as combining potions, strips, and nuggets with programmed weight or dimensional controls with angle cuts.

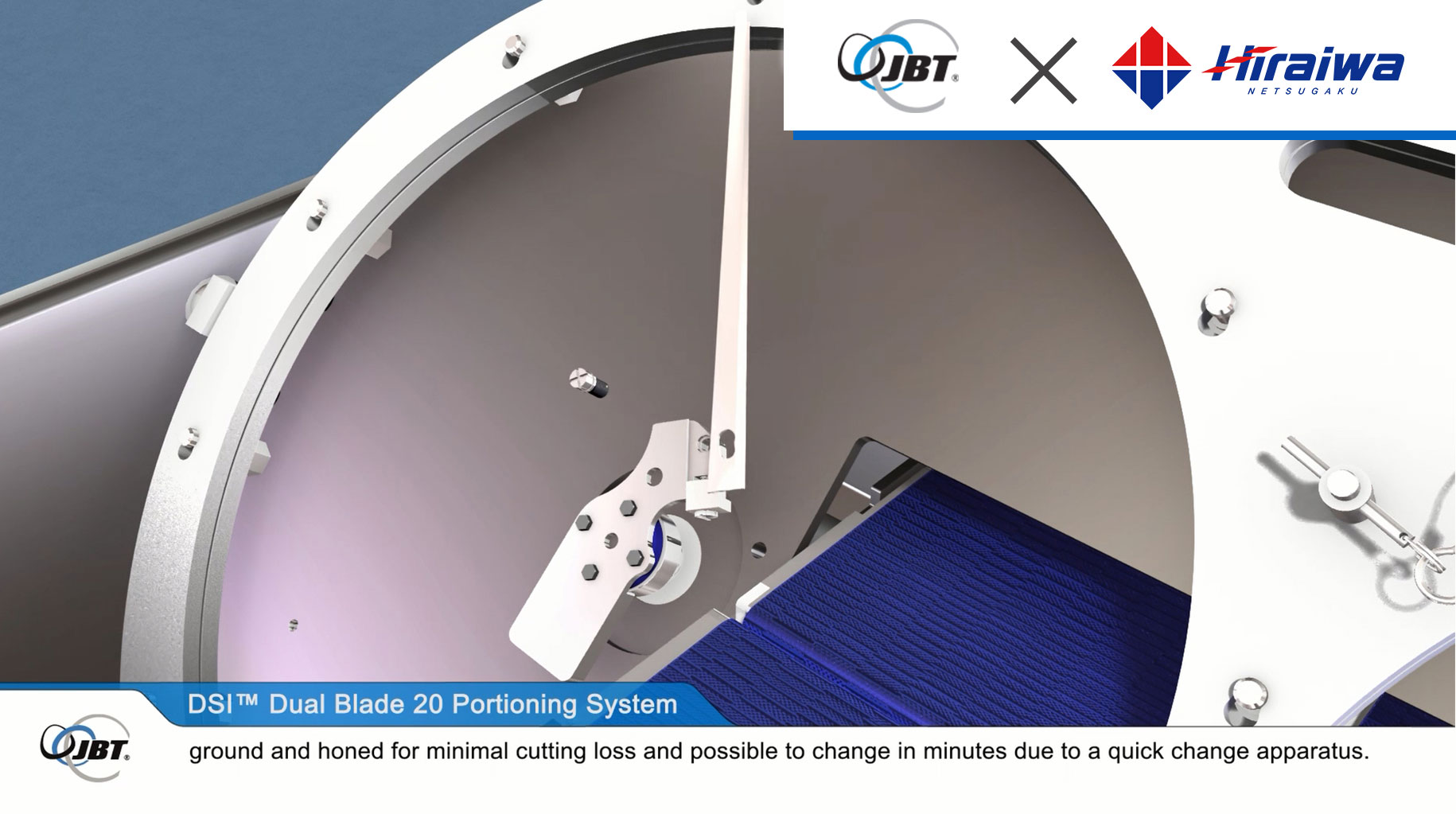

The blade rotates in the slight gap provided between the conveyors at the doorway. This blade is polished to minimize cutting loss and can be replaced immediately with a quick-change device. The

sharp DSI blade system and controlled conveyor gaps always provide consistent accuracy.

sharp DSI blade system and controlled conveyor gaps always provide consistent accuracy.

Conveyor systems do not require the frequent “belt readjustment”. The whole belt ,or a small section,can be easily removed in minutes for cleaning.

The DSI software minimizes the heat generated by the “servo motor” that controls the movement of each blade, and automatically controls the operation to always achieve the maximum processing capacity. Blade troubles are automatically detected, cost-effective, and the optimum blade cutting speed can be selected.

The DB20 system is always in a safe state due to the “DSI J-LOCK safety system”. It is designed not to move until the safety key is inserted.

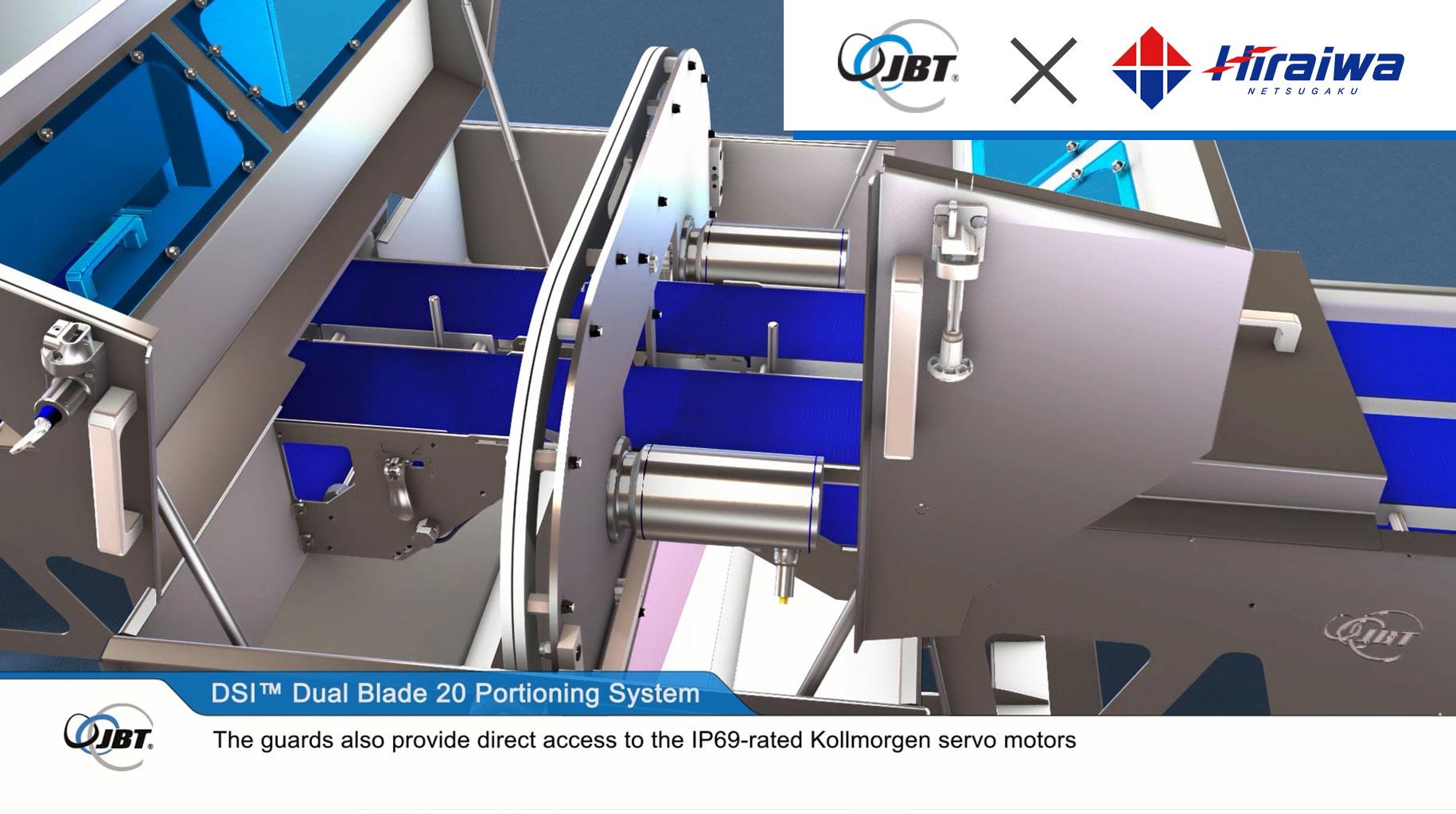

The guard part can be opened and closed safely, the cut area is easily accessible, and safe and secure inspection, maintenance, cleaning work, and blade replacement are possible.

This guard provides direct access to IP69 compliant servomotors to keep the blades hygienic. Unlike other companies’ products, the servo motor can be taken out for cleaning.

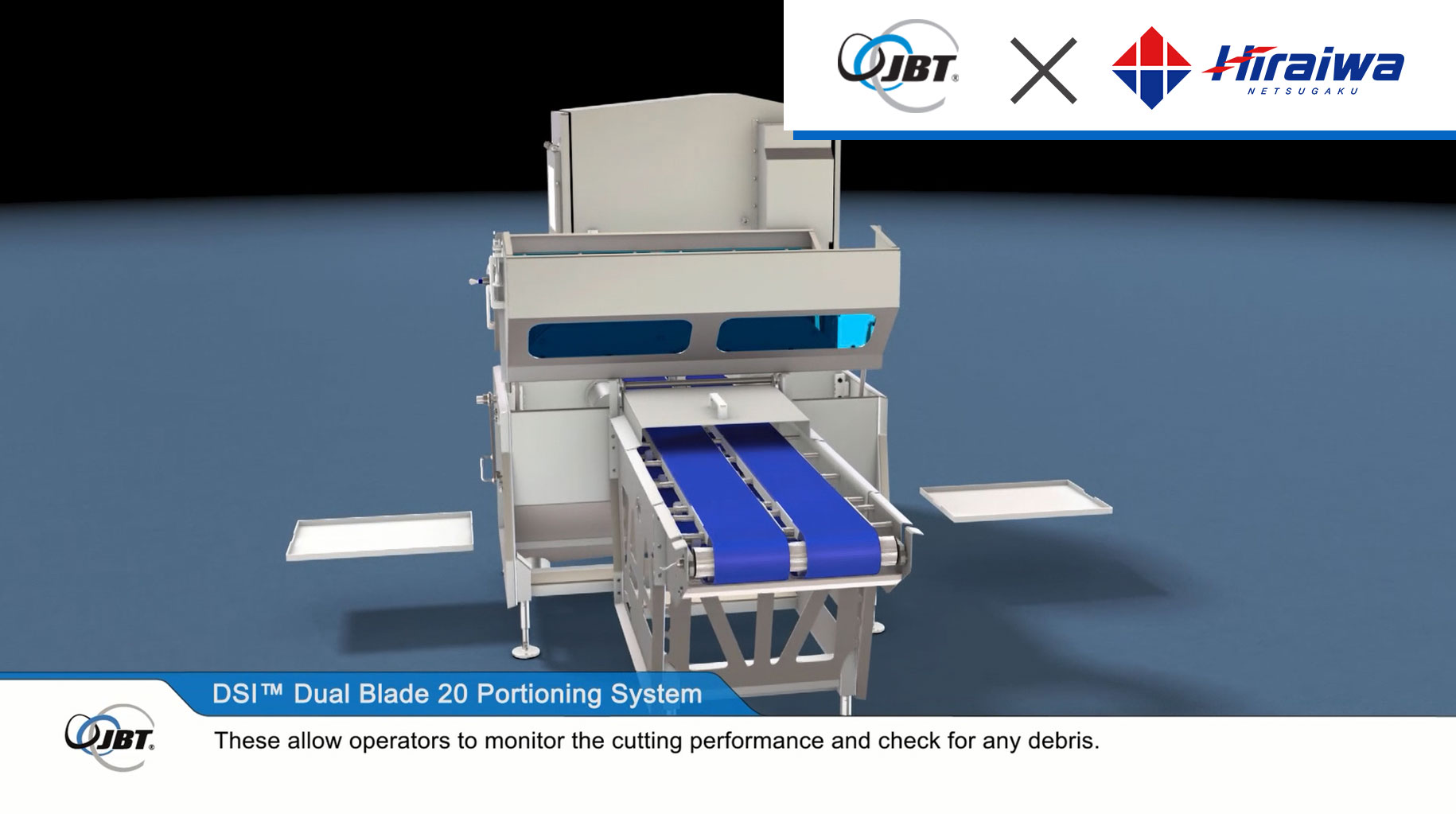

Detachable thin trays are installed on both sides of the housing. This makes it easy to check the cut status and dust. Tunnels are provided on the conveyor belts at the entrance and exit, making it safe for workers.

The DB20 system, like the DSI waterjet system, uses scanning technology, software and an operation panel. Therefore, the training time for workers can be minimized.

The B20 system also comes with a DSI Q-LINK data sensor. As a result, yields, throughput, and other important information can be shared on mobile devices for quick access to product and process information.

With the DB20 system, by combining it with other DSI and JBT systems, it has become possible to build a full line of processing lines such as potions, weighing, marinades, coatings, frying, cooking, and freezing.