Leave the meat processing machine also to Hiraiwa Netsugaku.

So far, we at Hiraiwa Netsugaku have introduced various process cooling systems for meat processing plants. We got experience and knowledge about the products (chicken, pork, beef) in many years, in order to add more value, not only the cooling system for the manufacturing process but also we provide the meat processing machine for productivity improvement, labor saving.

In addition, in order to increase the added value of our products, we test the process from cooling to processing every day in our own test room.

We have proposals for meat processing machines that only we can do as professionals in product cooling.

We have proposals for meat processing machines that only we can do as professionals in product cooling.

Based in Minami-Kyushu, the kingdom of chicken, pork, and beef production, we at Hiraiwa Netsugaku have solved process cooling problems at various slaughterhouses and meat processing plants. Based on this experience and data, we will provide further value by using freezers and chillers to cool products, which remains our strength. We conduct daily trial and error at our own test center in order to contribute to labor savings, automation, and further value-added creation for our customers’ products by proposing peripheral equipment. Our engineers specializing in meat processing machinery provide one-stop value-added services from the introduction of production line systems to maintenance.

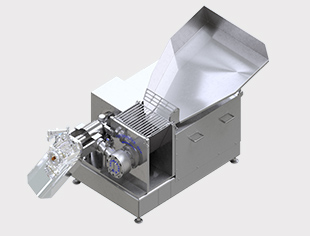

Hiraiwa Netsugaku started a partnership with TATS Corporation in 2021, and began sales of TATS Corporation’s bone and meat separators, equipment maintenance, and quality inspection of minced meat.

The bone and meat separator is a physical technology that separates the hardness (bones) and softness (meat) of raw materials by pressure and specific gravity. A rotating auger pushes up the meat under pressure and specific gravity, and the meat is cut and pushed outward using the principle of scissors and the corners of the holes in the screen.

【骨肉分離機 (TATSマスターBFP)】

- 鶏ガラから高品質でマネジナブルな新しいチキンミンチを製造。

- 本体は小型で背が低くコンベア不要。

- 2台のモーターで原料カット(押出)とミンチ(分離)を分業化。

- 生産ペースは時間当たりの投入原料次第。

- 歩留まりと品質の柔軟な管理が可能。

- 専門エンジニアよる徹底したアフターフォロー。

【生産ペース例】

(1400kg/H 歩留72%)

■ ブロイラーガラ

(1800kg/H 歩留62%)

■ 鶏トリミング

(1600kg/H 歩留70%)