Since its establishment in 1975, Hiraiwa Netsugaku has specialized in industrial freezing equipment and developed its business. We have provided our customers with a wide variety of equipment, ranging from freezing equipment for ships to production processing plants and distribution warehouses form eat, agricultural, and fishery products, and have earned the trust of our customers for our high

“technology” and “mobility”.

In recent years, we provide a complex range of services, starting with cooling systems for food production plants, and extending to peripheral production machinery and energy solutions.

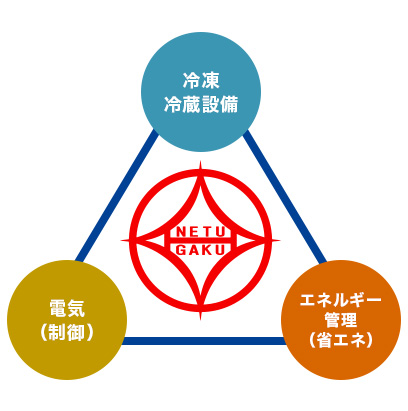

Industrial Cooling/Heating Business

Freezing and Refrigeration Equipment

Proposes freezing and refrigeration equipment to meet every requirement of our customers.

We provide a full range of services from design, construction, and maintenance to improve productivity and efficiency of freezing and refrigeration equipment

(Freezers/refrigerators, quick-freezers, ultra-low-temperature warehouses)

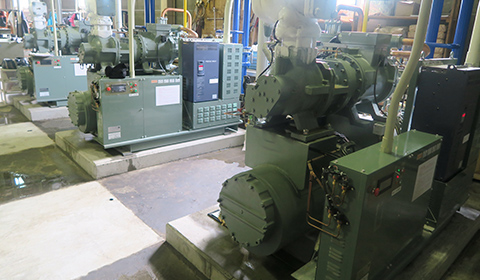

Natural Refrigerant Freezing Equipment

We provide a full range of services from planning to installation and maintenance of CFC-free equipment, such as Co2 freezers, Co2/NH3 dual systems, etc.

Water-cooled Chiller Equipment

We provide energy-saving water-cooled chiller equipment specialized in cooling poultry slaughter and processed foods, from research and planning to design, manufacturing, and installation.

Air-cooled poultry slaughter chiller system

We provide energy-saving water-cooled chiller equipment specialized in cooling poultry slaughter and processed foods, from research and planning to design, manufacturing, and installation.

Various Freezer Equipment

We propose optimal freezers that meet detailed specifications for livestock, agriculture, fisheries, and production products. We provide integrated services from planning to design and construction.

(Spiral freezer, tunnel freezer)

Low-temperature air-conditioning equipment

We plan the optimal work space for food factories by considering hygiene and production efficiency from all angles in a complex manner.

Ice Making Equipment

We provide a full range of ice machines from small to large (30 tons/day) for various applications, including plates, flakes, blocks, etc., from planning to production.

Electricity Business

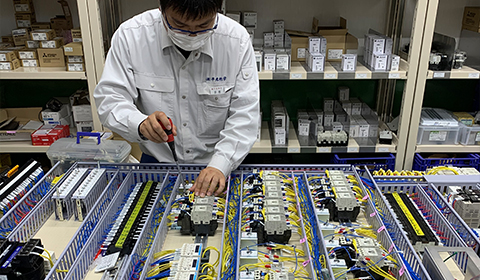

Control System Design and Control Panel Production

Based on thorough consultations to improve efficiency and optimization of production lines, we provide integrated services from system construction to control panel production (from relay sequence control to control using PLC and touch panels) through our unique design and programming.

(Automatic control systems, monitoring systems, safety measures, and contract manufacturing and development of various systems for freezing facilities)

High-voltage Power Receiving and Transforming Facilities

From high voltage power to special high voltage power, we provide integrated services including application, installation, inspection, and maintenance management by our qualified staff.

General Electric Facilities

We provide construction work related to electrical equipment for everything from factories to stores and homes.

Energy Management Business (Energy Saving Support)

Proposal of Energy Saving Solutions

We thoroughly examine all aspects of equipment and usage conditions in order to achieve a rational reduction in electricity consumption. Based on this, we plan and propose the optimal energy-saving equipment, services, and operational methods.

Self-consumption Solar Power Generation Equipment

Our professional engineers take full responsibility for solar power generation systems, from planning and design, selection and procurement, to construction and maintenance.

Furthermore, we thoroughly examine the equipment and usage conditions from all angles in order to achieve a rational reduction in electricity consumption. Based on this, we will plan and propose the most appropriate energy-saving equipment, services, and operational methods.

We can also obtain solar panels from both Japanese and overseas manufacturers and negotiate with power companies.

Self-consumption Solar Power Generation System

Industrial Rechargeable Battery

“Self-consumption solar power generation equipment” installed on factory roofs can be combined with industrial rechargeable batteries to enable factories to operate even during nighttime or rainy weather, when energy supply is unstable.

Engine Type Generator

We propose a variety of engine generators from large to small in terms of EPC measures and energy mix optimization.

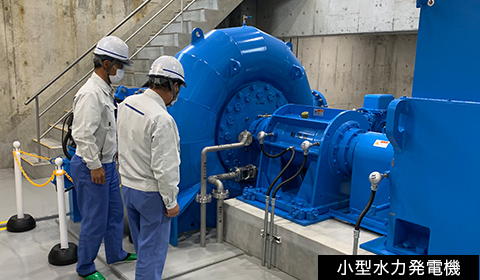

Renewable Energy EPC Business

Our specialized engineers provide comprehensive proposals for power generation systems based on renewable energy sources such as solar, wind, and biomass power generation, including planning and design, selection and procurement, construction, and maintenance management.

Small hydraulic power generator

Production Machinery Business (Labor-saving support)

Proposal and maintenance of various production machinery

We are quick to catch up with the latest information on cutting-edge equipment in Japan and around the world to contribute to labor saving and productivity improvement in food factories and make the optimal proposals. We build and follow up a meticulous maintenance system by taking advantage of our comprehensive capabilities.

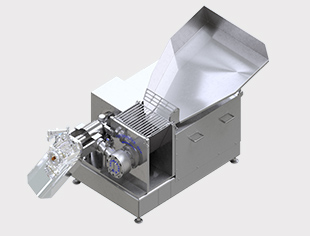

Bone and Meat Separator (TAT master BFP)

- We can produce high-quality, manageable chicken minced meat from chicken bones.

- The main part is small and short, and conveyors are not required.

- It is a division of labor with two motors for cutting materials(extrusion)and minced (separating).

- Production speed depends on the amount of input raw materials.

- It enables flexible control of yield and quality.

- We will do perfect follow-up by specialized engineers.

Production speed

(1400kg/H Yield rate:72%)

Broiler chicken bone

(1800kg/H Yield rate:62%)

Chicken Trimming

(1600kg/H Yield rate:70%)

Manufacturing Development and Testing

We perform product development, product processing tests, and cooling tests using our demo equipment.

For customers who are unable to visit us in distant locations, we can also make video recordings and offer proposals remotely. We can also flexibly handle raw materials from receiving to procurement.